Applications

ALUMINIUM COMPONENT DEBURRING

Foeburr offers best solution for aluminium component deburring. Combination disc brush which has different type of abrasive in a single brush will be useful for aluminium deburring application.

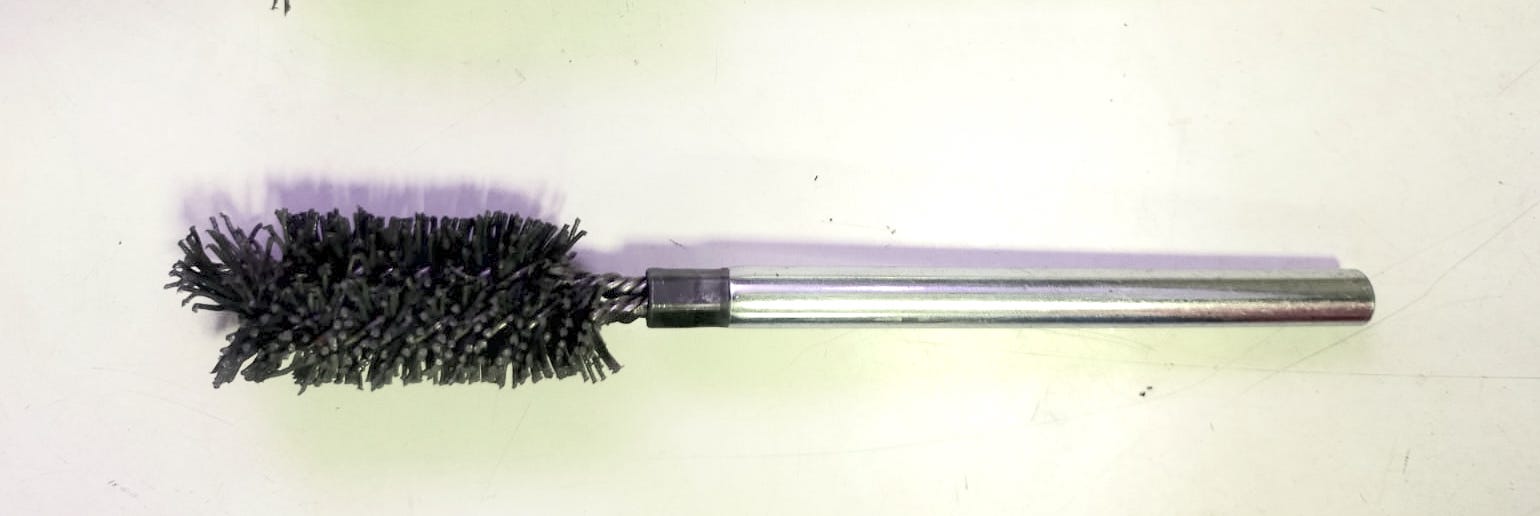

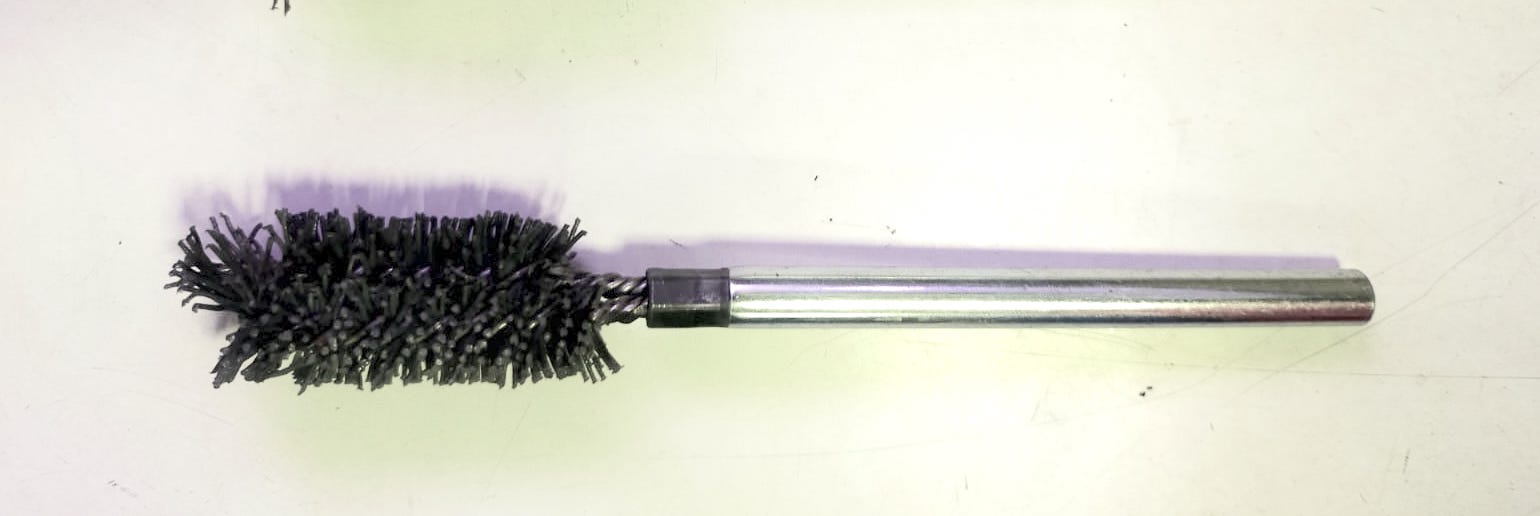

BLIND HOLE DEBURRING

Foeburr offers best solution for blind hole/ thread deburring application. Deburring of blind hole is a challenge. Because when using twisted wire brush the tip which has no bristle will hit the bottom. For this we can developed brush which has bristles in the front. So that the component will not get damaged.

CROSS HOLE DEBURRING

Foeburr offers best solution for cross hole deburring application. Burr will be generated at the intersection of two holes. One holes exit burr will be folded in the other side. This unreachable burrs can be deburred using twisted wire brush for small holes and wheel brush for bigger id.

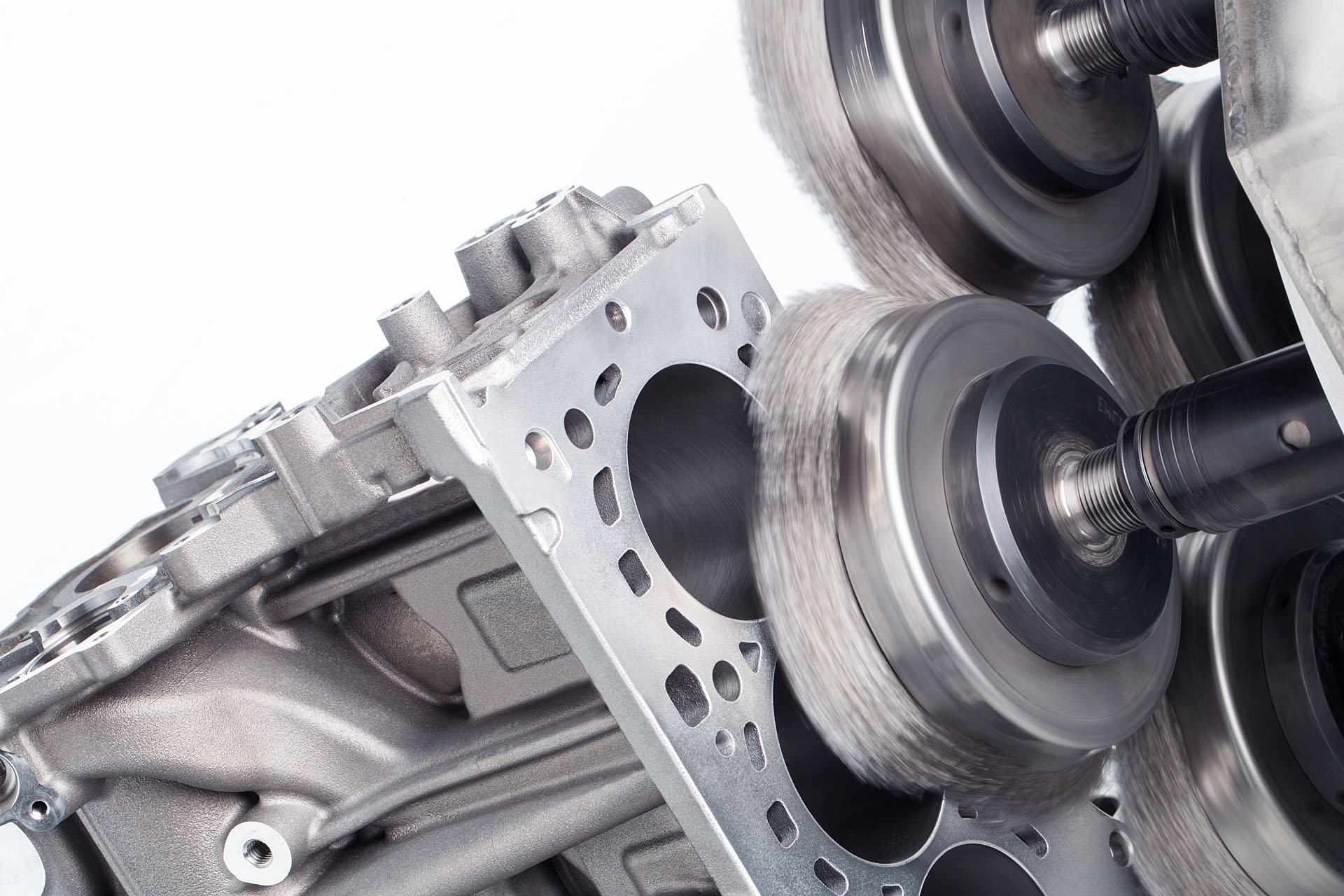

Cylinder head/ENGINE BLOCK DEBURRING

Foeburr offers best solution for cylinder head and engine block deburring application.

During face milling or face turning operations burr will be generated at the edges and in the groves in the face. This burr can be deburred using disc brush or wheel brush. The component will be deburred and small edge radiusing will be done.

Edge Rounding

Foeburr offers best solution for edge rounding application. With vast abrasive bristle and unique design edge radiusing can be done. Sharp corners will be removed.

FACE DEBURRING

Foeburr offers best solution for face deburring application. During face milling or face turning operations burr will be generated at the edges and in the groves in the face. This burr can be deburred using disc brush or wheel brush. The component will be deburred and small edge radiusing will be done.

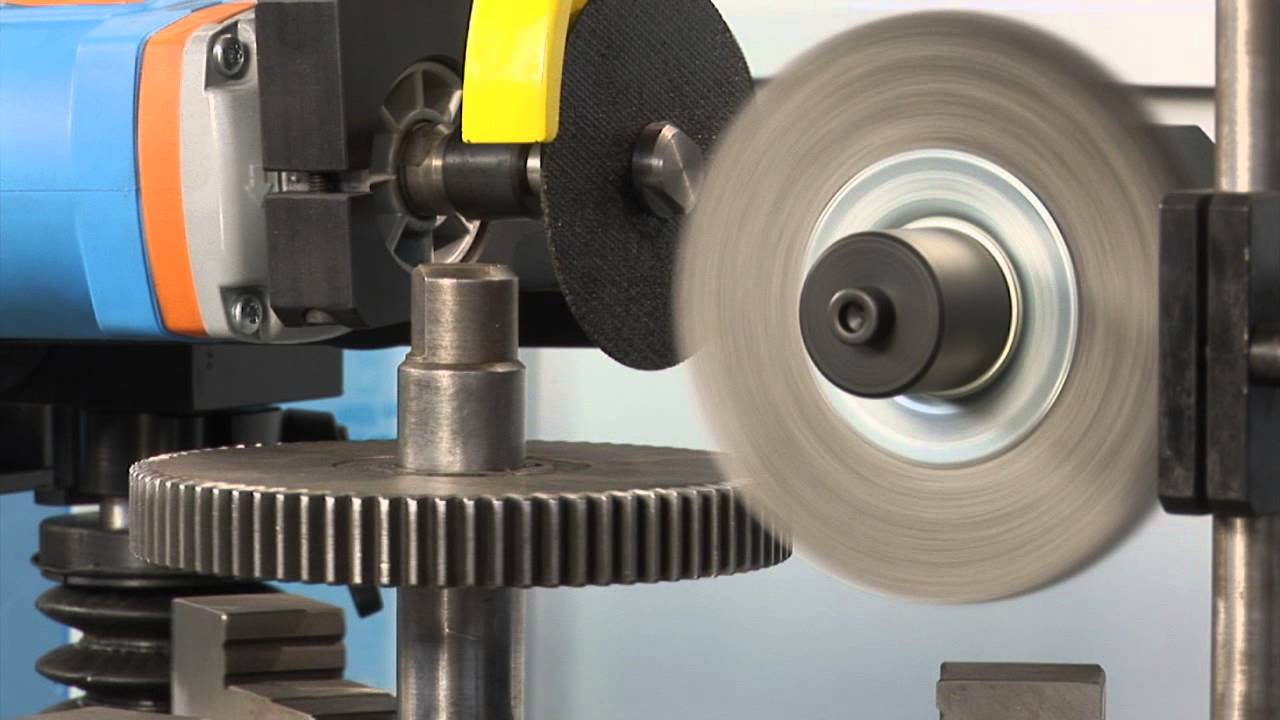

GEAR DEBURRING

Foeburr offers best solution for gear deburring application. During gear cutting burr will folded in the face. This can be deburred using wheel brush when rotated at a required rpm. The burr will be deburred.

OD DEBURRING

Foeburr offers best solution for od deburring application. Burr will be generated in the od when od grooving or hole or keyway operations. This burr cab be deburred using wheel brush.

OIL HOLE DEBURRING

Foeburr offers best solution for oil hole deburring application. Burr will be generated at the exit of the drilling process. For this twisted in wire brush will be suitable.

RUST REMOVAL

Foeburr offers best solution for rust removal application. The rust can be cleaned using wheel brush and disc brush.

THREAD CLEANING/DEBURRING

Foeburr offers best solution for thread cleaning and deburring application. Cleaning of thread and burrs in thread can be done using tube brushes. Burrs deposited in thread will not allow the corresponding bolts are screw to tighten. Twisted in wire brushes when run at particular rpm will do the job.

VMC DEBURRING

Foeburr offers best solution for deburring application in vmc. During face milling operations burr will be generated at the edges and in the groves in the face. This burr can be deburred using disc brush or wheel brush. The component will be deburred and small edge radiusing will be done.